Product Details

Similar Products

Product Description

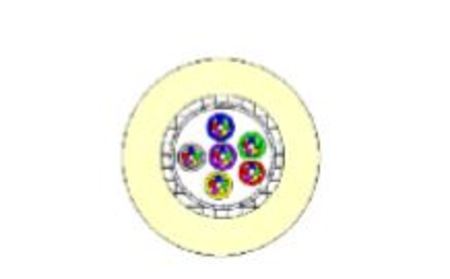

The 16FO (4x4) Riser Flex Tube Fiber Optic Cable SM G.657.A2 (Part number: 60026856) from Prysmian with 16FO. All-dielectric self-supporting cable (ADSS) is strong enough to support itself between poles, being used in optical networks, in self supported overhead power lines, suspended on poles or mounted on buildings being the best solution for quick and low-cost installations since the poles are already mounted from legacy networks.

Characteristics

- Optical fiber;

- Flex tube;

- Wired micromodules;

- Thermoplastic composite outer shell flame;

- Halogen free with UV resistance;

- Diameter of cable 7.6 mm;

- Weight 45 Kg/km;

Product Specifications

Fiber Type (ITU) - OS2 G.657.A2

Each type of single-mode fiber has its own area of application, and the evolution of these optical fiber specifications reflects the evolution of transmission system technology from the earliest installation of single-mode optical fiber to the present day. Choose the right fiber is very important for each project/installation. The OS2 G.657 standard single-mode fibers were developed to allow a better bending radius regarding the G.652 standard. For the OS2 G.657 fiber there are 4 subcategories: G.657.A1, G.657.A2, G.657.B2, G.657.B3.

The G.657.A2 fiber type is characterized by 7.5 mm minimum bending radius. These specifications of the G657 fibers allow to have a better cost-efficiency due to compact cable designs and reduced space requirements. Find some benefits when using the G.657.A2 fiber type:

- Low attenuation;

- Excellent macrobend performance (low bending radius);

- Flexibility;

- Cost-efficiency.

FOC Construction - Flex tube

While using a flex tube construction in cables, you can:

- Reduced installation time;

- Easier handling, particularly in fiber distribution and termination units;

- Fast access to fibers; easy to remove the module material with no tools required;

- Small quantity of grease, minimizing clean-up time;

- Avoid the risk of tube kinking (potentially causing attenuation increments or fiber breakage);

- Simple mid-span breakout enabling single module extraction to aid distribution.

The cable flex tube construction solution can be chosen for the following applications:

- Direct buried;

- Rodent resistant;

- Gunshot resistant;

- Facade;

- Indoor and outdoor;

- Hybrid;

- Underwater;

- Tunnel.

.png?locale=en)