Product Details

8 element All Dielectric Dry Core Design for Air-Blown installation into Micro-Ducts with 12fibers per tube

OFS

K1-3099

TP025458

A-DQ2Y 8x12 AW-Plus (1,1/1,45) Aufb.8 BK

New

Similar Products

Product Description

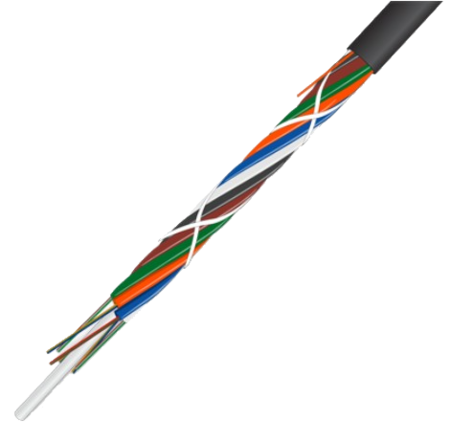

The 96FO (8X12) Air Blown Microduct Loose tube Fiber Optic Cable OS2 G.657.A1 Black (Part number: K1-3099) from OFS with 96FO. Air blown microduct fiber cable is optimised for injection into microducts and is used in optical networks, more specifically for use in Fiber-to-the-home (FTTH) and Fiber-to-the-Desk (FTTD) networks. This technique that is lower at cost, quicker and more environmentally friendly than traditional deployment, allowing a simpler instalation with less resources.

Loose Tube Fibre Optic Outdoor Cable with 8 buffer tubes and 12 AllWave+ fibers per tube. The MiDia GX Cable's small outer diameter and high fiber density help to maximize capacity in heavily congested duct systems where space is at a premium.

To implement or upgrade a modern metropolitan optical network, especially through urban areas, service providers can face challenges such as space limitations to excavation disruption to upgradability. To help make these intricate networks simpler and less costly, OFS developed the MiDia Microcable product line. An ideal solution for congested metro networks, the MiDia Microcables can help dramatically lower the cost of fiber optic deployment while increasing and enhancing capacity and fiber density in limited spaces. Whether your application involves overriding cables installed in existing ducts, deployment into unused inner ducts or greenfield “grow-as-you go” deployments, the MiDia Microcables are an excellent solution. By reducing or eliminating the need for expensive and disruptive excavation along with procuring costly rights-of-way, the MiDia Microcables offer a more cost-effective solution that requires fewer deployment resources. With the ability to deploy fiber only as needed, these microcables can help to defer initial investment costs while also allowing the flexibility to add newer fiber types or technologies as they become available.

Application

- Allows the use of smaller, more cost-efficient microducts for lower installation costs.

Characteristics

- Light weight;

- Compact microcable optimized to achieve longer air-blown installations distances;

- Provides outstanding macrobending and microbending performance.

Construction

- MiDia Micro GX cable with AllWave;

- Fibers are placed in water-blocking buffer tubes;

- Dielectric central member;

- Ripcor and a durable polyethylene jacket.

Product Specifications

Fiber Type (ITU) - OS2 G.657.A1

Each type of single-mode fiber has its own area of application, and the evolution of these optical fiber specifications reflects the evolution of transmission system technology from the earliest installation of single-mode optical fiber to the present day. Choose the right fiber is very important for each project/installation. The OS2 G.657 standard single-mode fibers were developed to allow a better bending radius regarding the G.652 standard. For the OS2 G.657 fiber there are 4 subcategories: G.657.A1, G.657.A2, G.657.B2, G.657.B3. The G.657.A1 fiber type is characterized by 10 mm minimum bending radius. These specifications of the G.657 fibers allow to have a better cost-efficiency due to compact cable designs and reduced space requirements.

FOC Construction - Loose tube

While using a loose tube construction in cables, you can:

- Pull and stretch without causing fractures from bending or tension;

- Have full resistant protection of the fiber core, cladding and coating (mechanical protection and UV protection);

- Reach optimized performances at extreme temperatures;

- Avoid the risk of environmental damage (including water damage).

The loose tube construction solution can be chosen for the following applications:

- Direct buried;

- Aerial;

- Duct;

- Rodent resistant;

- Indoor and outdoor;

- Water-blocking;

- Temperature endurance.

Jacket Material - PE

PE (polyethylene) is a versatile jacket material that offers good protection against moisture, abrasion, and chemicals. It is highly flexible and has a low coefficient of friction, which makes it easy to install and handle. PE is also resistant to UV radiation and can withstand a wide range of temperatures, making it a popular choice for outdoor and industrial applications. However, it is less flame-resistant than other materials, which may limit its use in certain environments.

.png?locale=en)

.png?locale=en)

.png?locale=en)

.png?locale=en)