Product Details

MLT Blown MicroCable

Similar Products

Product Description

The 144FO (12X12) Air Blown Microduct Loose tube Fiber Optic Cable OS2 G.657.A1 HDPE Black (Part number: D1519/144F) from Sental with 144FO. Air blown microduct fiber cable is optimised for injection into microducts and is used in optical networks, more specifically for use in Fiber-to-the-home (FTTH) and Fiber-to-the-Desk (FTTD) networks. This technique that is lower at cost, quicker and more environmentally friendly than traditional deployment, allowing a simpler instalation with less resources.

Application

- This cable is is suitable for Air-blowing.

Characteristics

- Single mode fiber 9/125

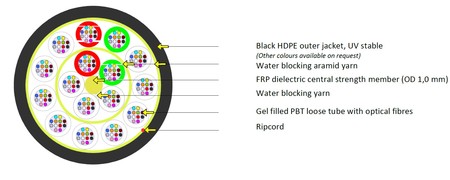

- Black HDPE outer jacket, UV stable

- Water blocking aramid yarn

- FRP dielectric central strength member (OD 1,0 mm)

- Water blocking yarn

- Gel filled PBT loose tube with optical fibres

- Cable outer diameter 8,0 ± 0,3 mm

- Cable weight 53 kg/km

- Outer jacket thickness 0,5 mm

- Loose tube diameter 1,5 mm

- Max. tensile strength 700 N

- Crush resistance test 1500 N

- Temperature range:

- Installation: -15 to + 50°C

- Operation -30 to + 70°C

- Storage -40 to + 70°C"

Construction

- Black HDPE outer jacket, UV stable

Product Specifications

Fiber Type (ITU) - OS2 G.657.A1

Each type of single-mode fiber has its own area of application, and the evolution of these optical fiber specifications reflects the evolution of transmission system technology from the earliest installation of single-mode optical fiber to the present day. Choose the right fiber is very important for each project/installation. The OS2 G.657 standard single-mode fibers were developed to allow a better bending radius regarding the G.652 standard. For the OS2 G.657 fiber there are 4 subcategories: G.657.A1, G.657.A2, G.657.B2, G.657.B3. The G.657.A1 fiber type is characterized by 10 mm minimum bending radius. These specifications of the G.657 fibers allow to have a better cost-efficiency due to compact cable designs and reduced space requirements.

FOC Construction - Loose tube

While using a loose tube construction in cables, you can:

- Pull and stretch without causing fractures from bending or tension;

- Have full resistant protection of the fiber core, cladding and coating (mechanical protection and UV protection);

- Reach optimized performances at extreme temperatures;

- Avoid the risk of environmental damage (including water damage).

The loose tube construction solution can be chosen for the following applications:

- Direct buried;

- Aerial;

- Duct;

- Rodent resistant;

- Indoor and outdoor;

- Water-blocking;

- Temperature endurance.

Jacket Material - HDPE

HDPE (high-density polyethylene) is a jacket material that offers excellent protection against moisture, chemicals, and abrasion. It is highly resistant to impact, making it ideal for rugged applications where cables are exposed to rough handling. HDPE is also UV-resistant, and it can withstand extreme temperatures, making it a good choice for outdoor and industrial environments. However, it is less flexible than other materials, which may make it difficult to use in certain applications.

.png?locale=en)

2Y%20%E2%80%93%20MT%20%E2%80%93%20250um.png?locale=en)

2Y%20%E2%80%93%20MT%20%E2%80%93%20250um.png?locale=en)