Product Details

OPUG 576/M24 G.652D NA SJ HDPE 1.5kN D19.3

Similar Products

Product Description

The 576FO (24X24) Duct Loose tube Fiber Optic Cable OS2 G.652.D HDPE (Part number: PTS13880051) from Optivine with 576FO. Conduit cables are underground cables, that may be conducted by duct or buried directly into the ground. There are several types of protections for this cable such as anti-rodent or double protection. Conduit cables are built to withstand harsh environments and are typically routed by pull or blow.

OPUG Fiber Optic Cables are designed for outdoor installation, usually in ducts. The aramid yarns helps the cable to have good tensile performance and temperature performance under extreme weathers.

Application

- For installation in ducts or directly burried

- Fully dielectric cable

- ~ IEEE Std P.1222 - Standard construction of

- composite fiber for use on electric utility power lines

- ~ IEC 60793-1 - Optical fiber Part 1: Generic

- specifications

- ~ IEC 60793-2 - Optical fiber Part 2: Product

- specifications

- ~ IEC 60794-1-2 - Optical fiber cables – Part 4:

- Sectional specification – Aerial optical cables

- along electrical power lines

- ~ EIA/TIA 598 - Color code of fiber optic cables

- ~ ITU-T G.652 - Characteristics of a single-mode

- optical fiber cable

Characteristics

- Core Type * G.652.D

- Fiber Count 576

- Tube Count 24

- Filler Count 0

- Cable Diameter (mm) 19.3

- Cable Weight (kg/km) 285.5

- Allowable Tensile Strength (short-term) 1.5 kN

- Water ingress resistance 1m, 24H, 3 samples

- Minimum Bending Radius (Installing) 20 x D

- Minimum Bending Radius (Operating) 10 x D

- Temperature (Installation) -10°C ~ +60 °C

- Temperature (Transportation and Operation) -40°C ~ +70 °C

- Life Span >30 yr

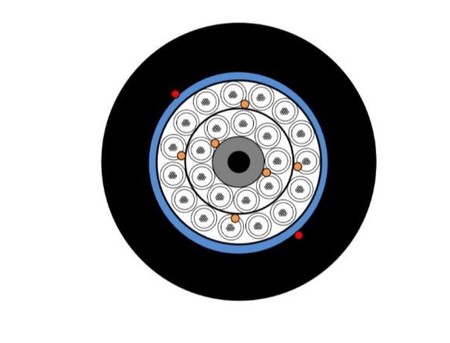

Construction

- Central Strength Member (FRP)

- PBT Loose Tube

- Optical Fibers

- Jelly

- Filler(s)

- Water Blocking Yarn(s)

- Water Blocking Tape

- Ripcord(s)

- Outer Sheath (HDPE)

Product Specifications

Fiber Type (ITU) - OS2 G.652.D

Each type of single-mode fiber has its own area of application, and the evolution of these optical fiber specifications reflects the evolution of transmission system technology from the earliest installation of single-mode optical fiber to the present day. Choose the right fiber is very important for each project/installation. The specification of the OS2 fiber is generally considered as the SMF standard for the single-mode fiber. For the OS2 G.652 fiber there are 4 subcategories: G.652.A, G.652.B, G.652.C, G.652.D.

The OS2 G.652.D single-mode fibers are the most used type of fiber for networking and communications applications. The OS2 G.652.D fiber type provides a zero dispersion at 1310nm wavelength therefor it is optimized for operation in the 1310nm Wavelength. The regular performance remains on the 1550nm wavelength.

Benefits of using the OS2 G.652.D fibers:

- Backward compatibility with earlier versions;

- Lower system cost;

- Offers zero water peak and seamless splicing;

- Lower splicing losses;

- Supports longer cable runs.

FOC Construction - Loose tube

While using a loose tube construction in cables, you can:

- Pull and stretch without causing fractures from bending or tension;

- Have full resistant protection of the fiber core, cladding and coating (mechanical protection and UV protection);

- Reach optimized performances at extreme temperatures;

- Avoid the risk of environmental damage (including water damage).

The loose tube construction solution can be chosen for the following applications:

- Direct buried;

- Aerial;

- Duct;

- Rodent resistant;

- Indoor and outdoor;

- Water-blocking;

- Temperature endurance.

Jacket Material - HDPE

HDPE (high-density polyethylene) is a jacket material that offers excellent protection against moisture, chemicals, and abrasion. It is highly resistant to impact, making it ideal for rugged applications where cables are exposed to rough handling. HDPE is also UV-resistant, and it can withstand extreme temperatures, making it a good choice for outdoor and industrial environments. However, it is less flexible than other materials, which may make it difficult to use in certain applications.

.png?locale=en)